Thermowood, aka heat-treated timber, is a stunning and eco-friendly material created by treating wood with heat instead of chemicals. Any wood product that has been heated to strengthen its stability and durability is referred to as Thermowood. Other names for this kind of wood product include heat-treated wood, thermal wood, and thermally modified timber—the entirely natural procedure of exposing the wood to very high temperatures (200˙). Lumber’s exclusive moisture content evaporates as a result. The wood is turned into a superior, resilient material and a more robust structure after undergoing this heat treatment. The procedure makes wood a good option for several construction and outdoor furniture applications. Stay with us to answer the question, ‘what is Thermowood.’

When all of the moisture in wood has been evaporated, a material known as Thermowood is produced. This is accomplished by putting the wood in a chamber and subjecting it to high temperatures for many hours – 96 hours at least. After being heated to between 185-212 degrees Celsius, the wood is cooled down quickly before going through the process again. All the OH (Hydroxyl) and H20 (Water) previously present in the wood cells are eliminated.

The instability of the wood is often caused by the presence of hydroxyl, which attracts free water cells into the wood. If you get rid of these components, you’ll have a far more durable and reliable product than Thermowood. It also indicates that there is no resin, which contributes to the excellent finish that is left behind.

Now that we have answered the question ‘what is Thermowood’, it’s time to answer the following question: What characteristics make Thermowood a good option for interior and exterior applications? The mentioned procedure causes the timber to change its chemical makeup and structural features. Some of the traits and qualities will change as a consequence of this. The heat-treated Scandinavian softwood timber is the source of the characteristics and features that go into manufacturing Thermowood cladding.

These traits and attributes consist of: High pressure, high heat, nitrogen, and water vapor are all applied to the material during making Thermowood, which helps to control the drying process. The wood is under strict monitoring throughout this treatment, which might last between 24 and 96 hours. The wood is exposed to temperatures ranging from 180 to 230 degrees throughout the treatment. The species controls every aspect. The wood loses all of its moisture and dries out from the middle when exposed to high temperatures for a lengthy period.

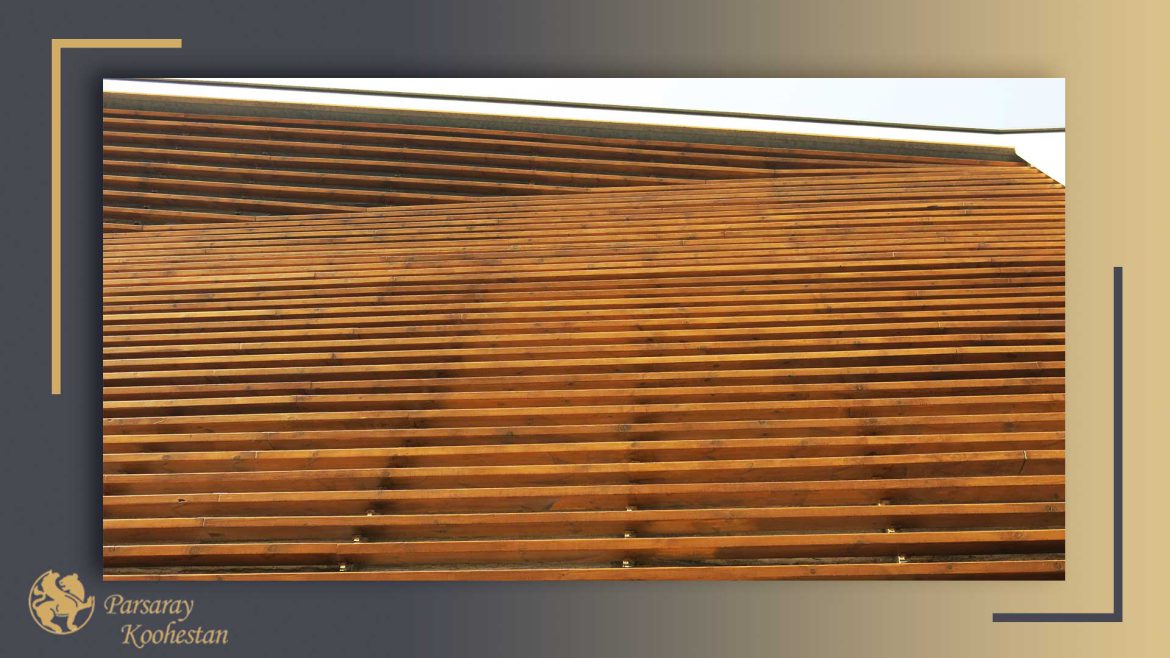

Wood that has been thermally treated may be used for cladding on exterior walls, facades, and other outdoor applications since reduced moisture levels suggest improved resistance to the weather.

The hemicellulose in the wood is destroyed during the heating process, which prevents the wood from containing any nutrients that may otherwise promote rotting and the development of fungus.

The wood used to make Thermowood comes from sustainably managed forests that have earned the PEFC certification. Additionally, at no point throughout the production process are any chemicals or foreign substances employed. Thermowood is a material that may be made sustainably using exclusively organic methods. The use of heat and the evaporation of water allows for the creation of Thermowood. This approach of organically treating wood is far more environmentally friendly than other chemical approaches.

Heat treatment is used to increase the average lifetime of the wood. Although this will vary based on the precise heat to which the wood is treated to determine how long it is projected to live. In general, the higher the temperature, the longer the life span. Heat treatment makes wood far more porous than raw wood, which significantly improves the treated wood’s insulation properties.

The wood is heated to a high temperature throughout the production process, which forces it to dry completely from the inside out and removes all of the moisture and glue. As a result, Thermowood does not react to changes in humidity as dramatically as untreated wood does. Consequently, there is a lower chance of swelling, breaking, and shrinking, making it much easier to keep its shape. Even when heated to high temperatures, the wood does not release any sap or resin. To see what is Thermowood most practical application, you can just read the following.

The thermally treated wood has many applications and may be utilized in various settings. However, considering the significant price difference, it is often used for projects that need more durable wood, such as the following:

Because of its strong resistance to moisture and decay, it is suitable for use in projects exposed to the elements. The following are some of its most common applications outside services:

The removal of the resin makes the wood not only aesthetically pleasing but also appropriate for use in interior construction projects like those listed below:

The heat treatment may be applied to both soft and hardwood. Pine, cedar, alder, and spruce are well-known tree species suitable for producing Thermowood.

If you are interested in purchasing Thermowood of the best possible quality, do not hesitate to contact us at Parsaray.com or submit a request for a price quote right now. Since we carry such a diverse selection of grades and profiles, you can be sure that we can assist you with whatever project you have. All of the Thermowood goods that we provide are of exceptional quality and can be purchased at pricing that is both reasonable and affordable.