The production of thermowood (or thermally-modified wood) may be an intriguing topic that some people are interested in getting to know. In general, wood is one of the first materials that has always been naturally and abundantly available to mankind. Therefore, the date of its use goes back a long time. It has been proven for centuries that burning the surface of wood makes it more resistant to outdoor use. In fact, thermowood is the same natural wood whose cellular structure has been changed due to the heat process. In this article, we are going to learn about thermowood production and its preparation for various uses such as facade wood, wooden parquet, etc.

In the production process of thermowood, water, steam, and high temperature are applied. Also, thermo paint is used to protect and care for the freshness of wood. These colors – also known as thermo resin – are produced in Canada and Germany. These paints have anti-UV and waterproof properties and increase the longevity of the product against sunlight and rain.

The wood used for thermowood is mainly produced from licensed forests in Europe and mostly in Finland. This wood is protected against the penetration of fungus, mold, and termites with a thermal mechanism without using chemicals. Relying only on heat, it has a much longer shelf life than ordinary wood. Also, the added heat in the thermowood production process changes the uniform color of the product and makes it more beautiful. Most of the time, thermowood is made from ash and pine wood, which increases its resistance to weather conditions and different geographical climates.

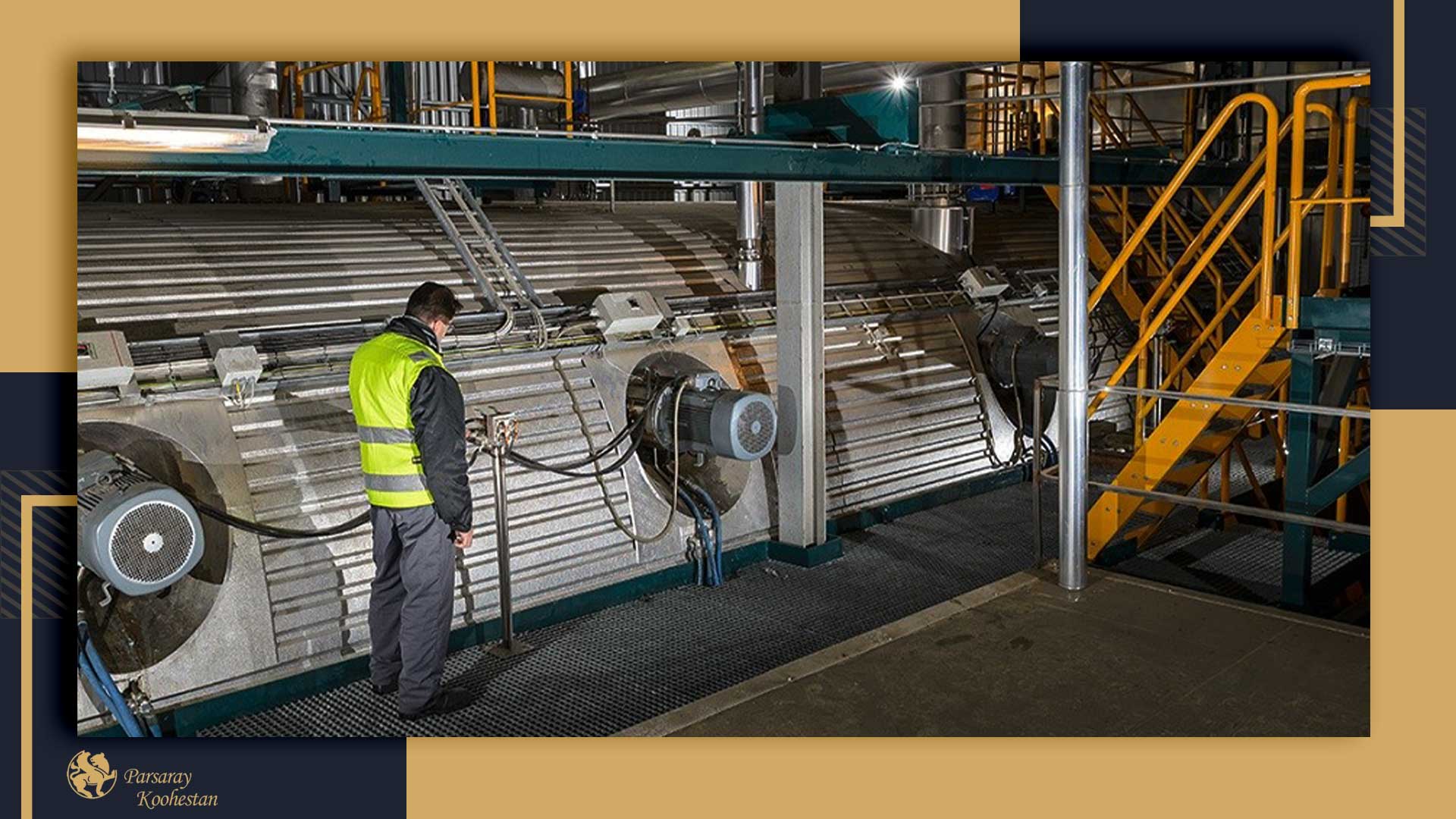

In the heating operation, water, steam, and high temperature are used. Materials that evaporate from wood are corrosive compounds. The heating equipment is made of stainless steel. To generate the heat needed in the thermowood production process, hot oil heating systems can be used that work with biofuels, petroleum fuel, or gas.

Other heating methods such as direct electric heating can also be used. In addition, to produce the steam required for this process, the equipment used must also have a steam generator. Gases vaporized from wood during the thermowood production process are managed by explosion and ignition. The main purpose of this is to get rid of the bad smell of gases caused by the evaporation of wood into the environment.

Thermowood production devices or furnaces are calculated based on cubic meters of interior space, and the smallest size of such furnaces is 18 cubic meters. That is, they produce 18 cubic meters of thermowood with each charge. The largest size of these furnaces is 50 cubic meters.

In the last stages of thermowood production, water is regularly sprayed on the wood to reduce its temperature. When the temperature of thermowood reaches 80-90 degrees Celsius, it is moistened again to reach the appropriate humidity. The result is the production of thermowood with 4-7% moisture.

Basically, all the harmful bacteria inside the wood and the substances that change the shape of the wood are destroyed. In general, in this 36-hour process, the wood transforms and a completely new type of wood emerges. Wood aeration takes place 2 to 3 hours after the heating operation and the wood is cooled afterward. Of course, a lot of care is needed to do this because the extreme temperature difference between the wood chamber and the outside air can cause it to crack and break.

During thermowood production, the wood must be re-moisturized so that it has suitable moisture for use. The final moisture level of wood has a significant effect on its functional properties because it is difficult to work with very dry wood. In addition, this issue has an effect on the price of tehrmowood. After airing, the final humidity of the wood should be 5 to 7%. Depending on the heating temperature and the type of wood, the airing phase can last 5 to 15 hours.

The duration of the drying phase depends on the initial moisture content of the wood and the thickness of the wood. Because the wood becomes elastic at high temperatures, as a result, its resistance to deformation in thermowood production is better than drying in traditional ovens. Because traditional kilns do not turn wood into thermowood, but only dry the wood. In fact, this process makes cheap thermal wood. Therefore, at this stage, the quality grading of thermowood wood is determined.

At the end of the thermowood production process and in conditions where the heat treatment has been done correctly and the internal stresses have been released, the thermowood does not undergo deformation after cutting, because it does not contain resin.

In this way, the required cutting force is reduced and the lifespan of the cutting equipment increases significantly. The only problem when cutting thermowood is the sawdust. Because thermowood has very little water, its sawdust is very fine and can easily spread in the surrounding environment. For this reason, proper equipment is needed to remove sawdust from thermowood.

The facilities used should be well sealed and effective enough because the high pitch of the cutting blade may cause the edges of the thermowood to be chipped. It is suggested to use finely serrated blades in the production process of thermowood because the useful life of blades made of carbide and similar materials is longer.

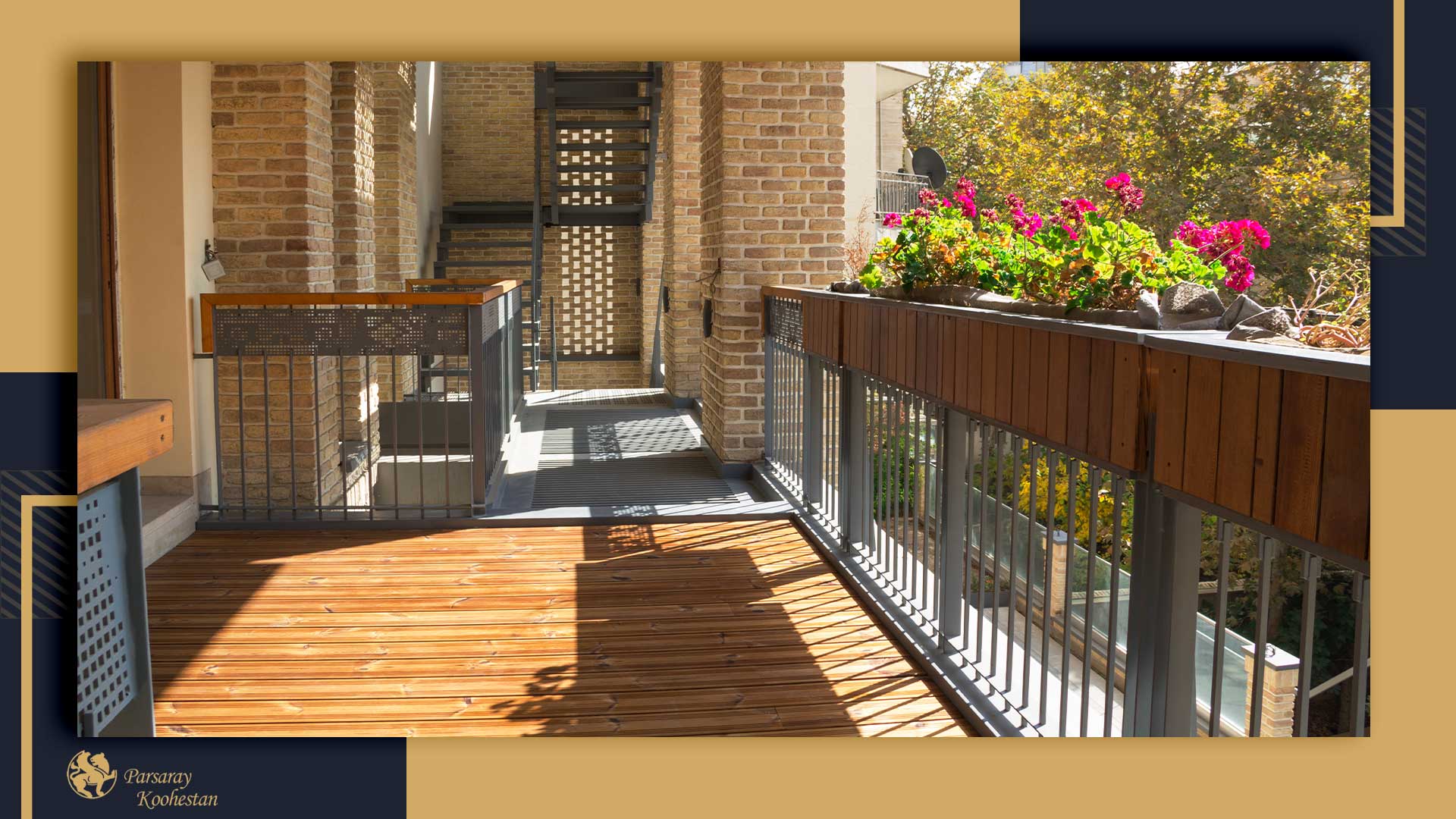

Thermowood is a wooden material produced using natural methods, heat, and steam. The thermal treatment process improves the technical properties of the wood and creates non-toxic, stable, erosion-resistant thermowood. This resistant material can be used indoors or outdoors, in any kind of weather.

Pars Aray Koohestan has a brilliant history of producing high-quality thermowood in Iran. Depending on your application, we offer you the best thermowood at the most suitable price. Just contact our experts to purchase and install thermowood structures.